Others undergo some chemical modification on heating and can not be softened by reheating; these are thermosetting plastics. Some natural substances could be formed in this way; gutta percha, a latex derivative imported from Malaya after 1843, was moulded into small ornamental objects. Next, chemists experimented with organic substances of natural origin to produce plastic materials. Christian Friedrich Schönbein, of the University of Basle, produced cellulose nitrate by the action of nitric and sulphuric acids on paper (cellulose) and this could be shaped into attractive vessels.

This led the metallurgist and inventor Alexander Parkes to develop the first commercial plastic, cellulose nitrate with camphor as a plasticizer. He exhibited this Parkesine at the International Exhibition of 1862, but the company he set up to manufacture it failed in 1868. More successful was the American printer John Wesley Hyatt, whose attention was turned to cellulose nitrate by the offer of a prize of $10,000 by Phelan & Collander, makers of billiard balls who had run short of ivory, thanks to the efforts of the elephant hunters, and were desperate for a substitute. After experimenting Hyatt filed a patent covering the use of a solution of camphor in ethanol as a plasticizer for the cellulose nitrate, or Celluloid, as it came to be called.

It could be shaped and moulded while hot and on cooling and evaporation of the camphor, became ‘hard as horn or bone’. Hyatt prospered and set up plants to make celluloid in Germany, France and Britain, where it became a popular material, particularly for detachable collars and cuffs. It was found that cellulose acetate could also be used, with the advantage that it was non-inflammable.

Towards the end of the century it was available in thin film, and could be used as a base for photographic emulsions. Photography and the new art of cinematography made increasing demands on cellulose nitrate, which reached a production peak in the 1920s, when it began to be replaced by other less flammable plastics derived from cellulose. A notable use of cellulose acetate was as a covering for aircraft wings, rapidly developed during the First World War.

The second semi-synthetic plastic was formed from the reaction between casein, the main protein in milk, and formaldelyde, announced in 1897 by Spitteler & Krische in Germany. The manufacture of the first casein plastics, giving a hard, horn-like material, began three years later and has continued ever since, being especially suitable for buttons. More important was the announcement in 1909 of the first thermosetting plastic by a Belgian who had settled in the USA, Leo Hendrik Baekeland. The German chemist Baeyer had observed in 1872 that phenol and formaldehyde formed a hard, resinous substance, but it was Baekeland who exploited the reaction to produce commercially Bakelite, a versatile material resistant to water and solvents, a good insulator, like other plastics, and one which could be easily cut and machined.

Chemists were now investigating the structure of such substances as cellulose, produced in plants, with long-chain molecules. This led to the notion that such molecules might be produced in the laboratory. Also there was a growing understanding of the relationship between physical properties and molecular structure, so that it might be possible to design large molecules to give materials of certain desired characteristics. More than any other, it was Hermann P. Staudinger in Germany who achieved an understanding of the processes of polymerization, or forming large molecules from repeated additions of small, basic molecules, upon which is largely based the staggering progress of the plastics industry since the 1930s.

For this work Staudinger was awarded the Nobel Prize in Chemistry in 1953. The other great name in fundamental research in this field is Wallace H.Carothers, who was engaged by the Du Pont Company in the USA in 1928 to find a substitute for silk, imports of which from Japan were being interrupted by the political situation. Carothers developed a series of polymers known as polyamides; one of these mentioned in his patent of 1935 was formed from hexamethylenediamine and adipic acid. Production of this polyamide, known as Nylon, began in 1938 and the first nylon stockings appeared the following year; during the first year, 64 million pairs were sold.

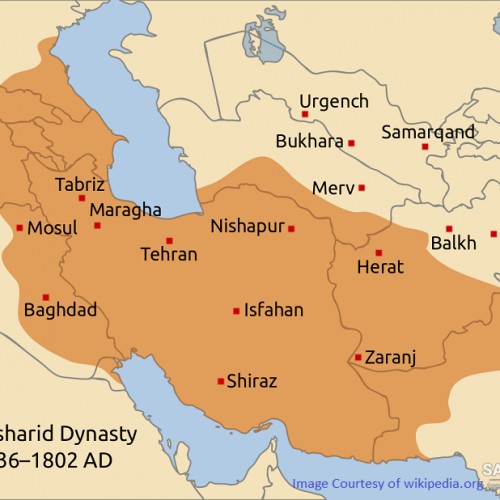

Another extremely important result of Carothers’s researches was synthetic rubber. He found that when polymerizing acetylene with chlorine, the product, polychloroprene, was a superior synthetic rubber, better known as Neoprene. Commercial production began in 1932. Meanwhile, in Germany a general purpose synthetic rubber was developed as a copolymer of butadiene and styrene. These products assumed desperate importance after the Japanese overran the Asian rubber plantations in 1941, cutting off the Allies’ source of this essential material.

Rubber

Rubber