To dye cloth successfully so as to withstand the action of air, light and wear, dyers settled down to use scarcely more than a dozen or so dyestuffs and this limited range lasted up to the middle of the nineteenth century. It was only then that progress in organic chemistry enabled the secrets of the structure of the chemicals concerned to be unravelled and this paved the way for the synthetic dyestuffs industry, adding enormously thereby to the stock of colouring materials at man’s disposal. It is useful here to distinguish between vat and mordant dyes. In vat dyeing, the dye substance, insoluble in water, is converted by chemical treatment into a substance that is soluble; the cloth is then steeped in a solution of the latter and left to dry. The action of the air forms, by oxidation, the colour of the original substance on the fibres of the cloth. Indigo and woad were used in this way. With mordant dyeing the cloth is first boiled with a solution of the mordant, usually a metallic salt, and then again in a solution of the dyestuff. Different mordants can form different colours with the same dyestuff. Since antiquity the mordant used above all was alum, a term now commonly taken to mean a double sulphate of aluminium and potassium crystallized with 24 molecules of water. Before its composition was known, towards the end of the eighteenth century, the word was more loosely used to mean a white astringent salt to cover several different substances. The use of alum as a mordant for dyeing cloth red with madder can be traced back to around 2000 BC in Egypt.

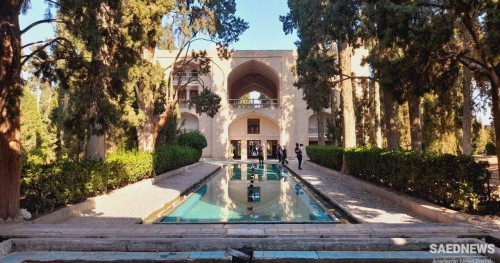

The mediaeval dyer used alum in large quantities, sometimes from native alum-rock from Melos or other Greek islands, a source since Roman times. Various kinds of alum were imported from Middle Eastern regions, or the mineral alunite was converted to aluminium sulphate by roasting. Alternative sources were eagerly sought, particularly after eastern supplies were cut off by the advance of the Turkish Empire in the fifteenth century. Fortunately a large deposit of the mineral trachite, which yielded alum on being treated with sulphurous volcanic fumes, was found at Tolfa in the Papal States. This led to a highly profitable papal monopoly in the alum trade. After the Reformation, Protestant countries sought other, local, sources. In England, for example the shale found in Yorkshire was used; roasting oxidized the iron pyrites it contained to ferrous sulphate, which at a higher temperature decomposed and converted the aluminium silicate also present to alum. Similar processes were carried on all over Europe. They remained inefficient until they were better understood; when it was realized that the aluminium ion was the active agent in mordanting, aluminium sulphate gradually replaced alum.

Of the dyestuffs themselves, the only successful blue dye known before the last century was indigotin, derived from the indigo plant in tropical areas and from woad, with a lower content of indigotin, which grew widely throughout Europe. Indigotin is insoluble and so could not be used in a dye bath. The plants were therefore left to ferment to produce the soluble indigo-white. The cloth was steeped in the liquor and as it was hung out to dry, oxidation to indigo-blue took place. The Egyptians of 1500 BC were dyeing with indigo and some of their fabrics have retained their blue colour to this day. In GraecoRoman and mediaeval times, woad was chiefly used to dye blues. For yellow, the earliest dye appears to have been safflower. It had a long history for it has been detected in mummy wrappings of 2000 BC and was still in use until quite modern times. Saffron, the stigmas of the saffron crocus, was also used, hence for example the name of the town Saffron Walden in Essex, a noted centre for the flower in the Middle Ages. It has long been used in India for dyeing the robes of Buddhist monks. The most widely used yellow dye in mediaeval times was weld or dyers’ weed, which gave a good yellow on cloth mordanted with alum.

The madderplant, derived from a species of Rubia which grows wild in the Mediterranean and Near East regions, also has a long and distinguished history. Again, the Egyptians were using it around 1500 BC, to dye cloth red. From Graeco-Roman times a red dye was also obtained from various species of Coccus, insects parasitic on certain plants, such as cochineal. The Arab word for coccus was kermes, from which our word crimson is derived. When cardinals began to sport their red-coloured robes in 1464, the hue was produced from kermes with alum as mordant—a crimson rather more subdued than the brilliant scarlet we know today. The latter became possible in the seventeenth century using cochineal mordanted with a tin salt. A highly prized colour in the ancient world was a dark brownish-violet produced from several species of shell fish including Purpura, hence the name purple. The purple-dyeing industry tended to be located in Mediterranean coastal regions and the Phoenician towns of Tyre and Sidon were notable centres of the trade.

Of the dyer himself and his methods rather less is known. His was a messy, smelly occupation and he tended to keep to himself the secrets of his craft. It was a skill learned from others and by practice which probably changed little until the first printed accounts began to appear. The craft was virtually static until the late eighteenth century when rapid changes in the textile industry demanded improvements in dyeing techniques. But the range of dyestuffs available remained the same until the mid-nineteenth century, when the ancient craft began to be transformed into a science-based technology.

Industrial Revolution and Increasing Demand for Glassware

Industrial Revolution and Increasing Demand for Glassware